design & development

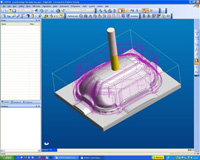

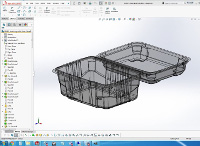

The use of CAD software systems such as Delcam, SolidWorks, and DriveWorks together with state of the art machining capabilities enables PFL to fully integrate the design & manufacturing processes from initial concept through to final machining. Whilst fully embracing contemporary technology PFL also recognises the importance of traditional tool and pattern making skills. The incorporation of both modern and traditional techniques allows PFL a unique flexibility in their approach to customer’s requests. A written brief, sketch or description is sufficient for our design team to commence the process. Concept drawings, 3D modelling images and product visulisations are produced for viewing by the client; these can be viewed as hard copy drawing, photographs or by the use of dedicated e-viewing programs. A clients own computer aided designs can be imported into the modelling software used by PFL and employed to generate designs and or machining programs. From an agreed design detailed drawings and machining programs can be prepared to produce sample products, moulds or complete finished thermoforming tooling. From the original concept, through design, realization and sample products to the final machining procedures, the process is continuous and integrated.

|

|